Zinc nickel plating for a major European automotive OEM

Services: Zinc Nickel Plating

End User

Major European Automotive OEM

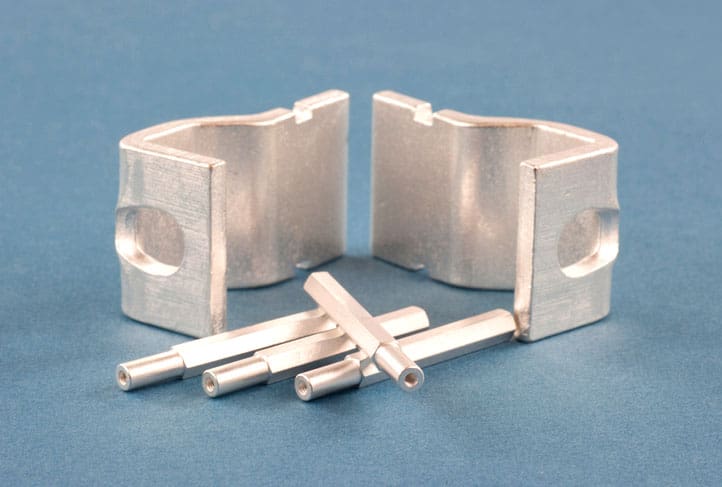

Component Description

This uniquely designed component with integral free moving washer is used on the aluminium wheels on a range of executive cars. Mounted in the aluminium casting it is important that no galvanic corrosion is set up. This is why the designers chose zinc nickel alloy electroplating, which unlike traditional zinc plating can be safely mated to aluminium. Additionally, tight tolerance is an issue with assembly being automated the torque characteristics need to be consistent.

Coating Requirement

The crucial issue is to maintain this tight tolerance when processing large volumes every day. Process control and repeatability is essential. A more unusual requirement was to maintain a predetermined dark black colour as these components are readily visible in the showroom. Moreover, the coating has to achieve in excess of 720 hours salt spray performance. Tight tolerance even on the inside of the component and control of the torque characteristics were essential.

Solution Supplied

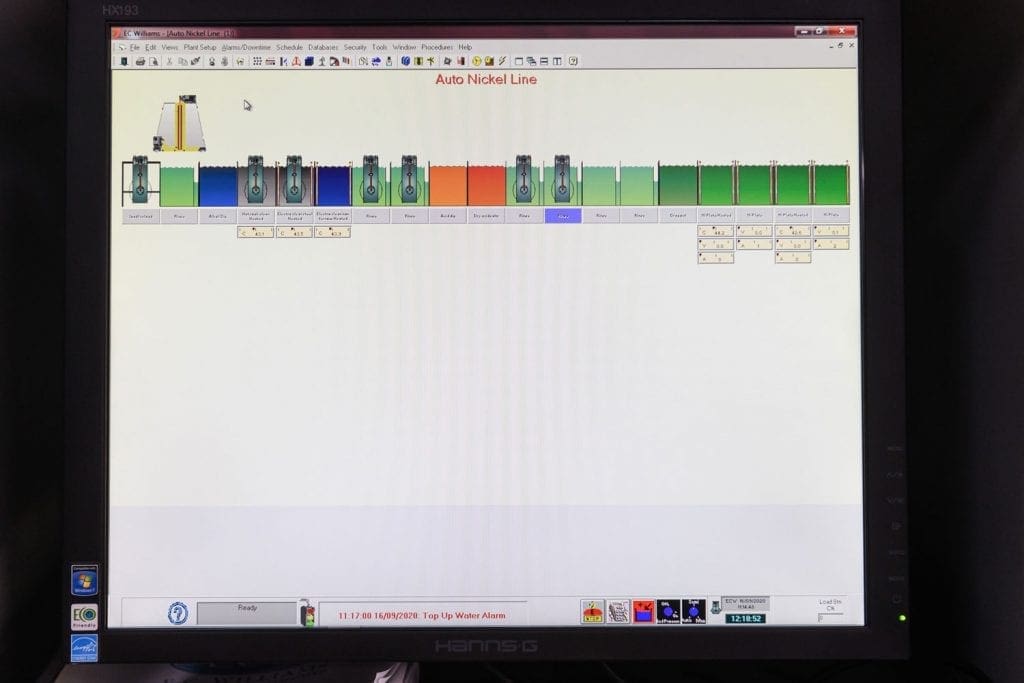

Using accurately specified barrel loadings and rectifier settings we have been able to control the coating thickness within the tight tolerances specified – even in bulk production. Naturally the coating is also RoHS and compliant, meeting end of vehicle life regulations. Finally, a torque controlling lubricant is applied.

View Our Services

Zinc Nickel Plating

Our Zinc Nickel Plating services provide superior corrosion resistance and meet the rigorous requirements of major automotive specifications. This alloy finish is ideal for components exposed to harsh conditions, including marine environments and high-temperature applications. EC Williams has extensive experience in delivering zinc nickel plating to automotive and aerospace industries.

Copper Plating

Copper Plating is often used as an undercoat for tin, silver, or nickel plating, enhancing corrosion resistance and providing a strong base for additional coatings. It can also be used as a finish in its own right, offering conductivity and aesthetic appeal. Whether for decorative or functional purposes, our barrel and rack plating facilities ensure a uniform and high-quality finish.

Nickel Plating

Nickel Plating provides a highly durable finish with excellent corrosion resistance and wear properties. At EC Williams, we offer barrel Nickel Plating for a variety of substrates, including steel, brass, and zinc die-cast components. Nickel is frequently used in applications requiring both aesthetic and functional performance, such as electrical components and fasteners.

Tin Plating Services at EC Williams

At EC Williams, we provide both bright and matt tin plating options, depending on your application. Tin plating offers excellent corrosion resistance, solderability, and electrical conductivity, making it ideal for use in electronics, power distribution, and automotive components. Our jig and barrel plating facilities can accommodate projects of various sizes, ensuring flexibility and precision.

Zinc Plating

Zinc Plating is one of the most versatile electroplating finishes available. At EC Williams, we provide zinc plating with a range of passivates, including clear, yellow, black, and olive drab, to suit various applications. Zinc plating offers excellent corrosion resistance, making it ideal for fasteners, brackets, and automotive components.

JS500 Zinc Plating Services

Our JS500 zinc plating offers enhanced corrosion resistance by applying a zinc-plated finish with a silicate sealant. This process meets the requirements of both the ELV and RoHS directives, making it a popular choice in the automotive industry for components that need to withstand harsh environmental conditions.

Trivalent Yellow Passivate

This Trivalent Yellow Passivation process enhances the corrosion resistance of zinc-plated parts. It is chromium(VI)-free, making it an environmentally friendly option that complies with modern safety standards, including RoHS directives. This finish is ideal for automotive and industrial applications requiring reliable corrosion protection without hazardous substances.

Stainless Steel Coatings

Our Stainless Steel Coating services include passivation, which enhances both the appearance and corrosion resistance of stainless steel parts. Passivation removes contaminants from the surface of the steel, forming a protective oxide layer that prevents rust and improves longevity in aggressive environments.