Electro Tin Plating Services at EC Williams

Call 0121 236 2524 For Your Free No-Obligation Quote

With a legacy dating back to 1921, E.C. Williams has firmly established itself as the hallmark of quality tin plating in the UK, and most prominently, Birmingham.

Over the years, our commitment to quality and innovation has made us the go-to choice for businesses across various sectors, be it automotive, electrical, or electro-mechanical for all things electro-tinning.

Our Tin Plating Services

Tin plating (often referred to as electro tinning) is not just about adding a layer; it’s about enhancing functionality, aesthetics, and ensuring longevity. At E.C. Williams, we understand these nuances and have tailored the two types of tinning services accordingly.

- Bright Tin Plating: This technique is renowned for its glossy, mirror-like finish. Besides its aesthetic appeal, bright tin plating offers excellent solderability. It’s a favourite among industries where both appearance and functionality are paramount. The bright shine not only amplifies the look but also provides a smooth surface, reducing friction.

- Matte Tin Plating: Matte, as the name suggests, provides a uniform, non-reflective finish. Perfect for industries where glare reduction is essential, this plating ensures uniformity without compromising on protection. The matte finish is often preferred for its contemporary look and the ability to offer an understated elegance to components.

World-Class Tin Plating Facilities for Unmatched Results

With the increasing demand for Electrical Vehicles, the demand for tin plated components is growing. At E.C. Williams, we have invested in state-of-the-art processing plants, boasting one of the largest and most advanced tin plating facilities in the UK. Our modern barrel and vat processing facilities enable us to efficiently handle both small and large batch sizes.

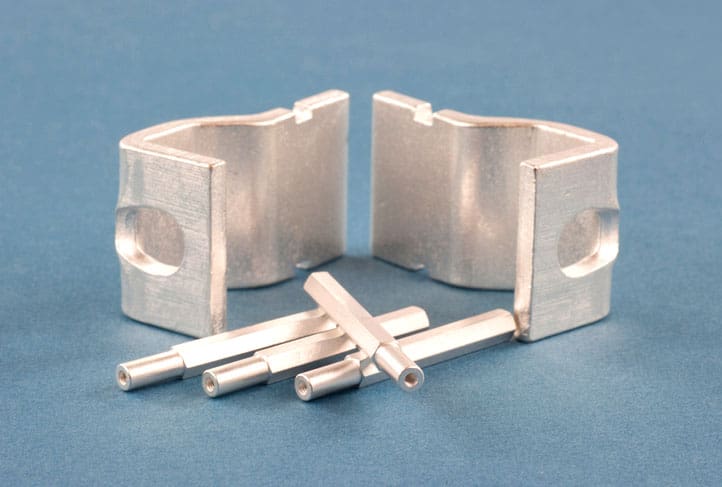

We electro tinplate a diverse range of components, including:

With our advanced equipment and meticulous electro tin plating techniques, we ensure consistent and high-quality tin plating results that meet industry standards.

Copper Plate Undercoats For Tin

As a reputable tin plating company, we have gained extensive expertise in tin electroplating. Our skilled team is proficient in delivering superior metal plating finishes, including bright electro tin plating and matte (pure) tin plating. For enhanced performance and durability, we also offer a copper plate undercoat for tin. This is particularly beneficial when working with brass substrates. Whether you require solderable plating, dull plating, or bright tin plating, EC Williams caters to a wide range of needs and applications.

Advanced Coating and Finishing Solutions

Our prowess extends beyond just plating. We offer a suite of advanced coatings that accentuate the performance of the plated components:

- Torque Tension Products: These are vital in maintaining uniform tension, ensuring components remain firmly in place.

- Lubricants: An essential post-plating addition, lubricants diminish wear and tear, prolonging component life.

- Passivates: These smart solutions enhance corrosion resistance, ensuring your components last longer in challenging environments.

- Torque Controllers and Silicate Sealants: While the former maintains desired torque levels, the latter offers an impregnable barrier against external factors.

- Identification Dye: This aids in the swift identification of components, streamlining processes.

Why EC Williams?

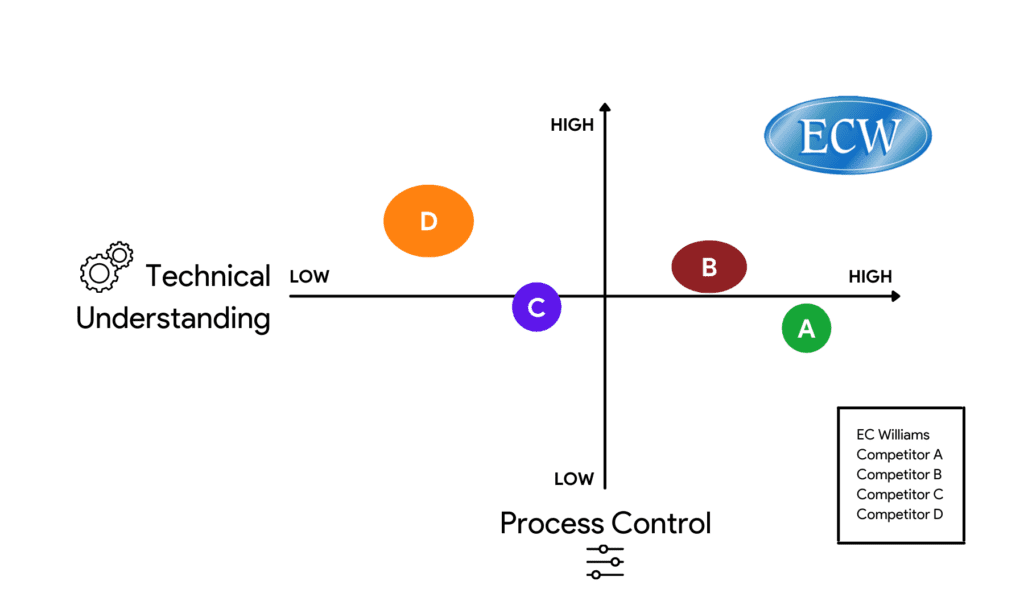

In the ever-evolving realm of tin plating and electro tinned parts, we’re not just players; we’re game-changers. Our continual investments in cutting-edge facilities ensure that our clients always receive the best. Whether you’re catering to the burgeoning Electrical Vehicle sector or any other, our tin plating solutions are tailor-made for excellence.

To certify the tin coating thickness, we utilise advanced X-Ray Fluorescence test equipment. This equipment allows us to quickly and accurately measure the exact amount of tin deposited, ensuring precision and adherence to your specifications.

How can I collaborate with E.C. Williams?

It’s simple! Use our contact form OR dial 0121 236 2524. Our team will reach out within 48 hours.

For those in the know, E.C. Williams is synonymous with excellence in tin plating.

We invite you to embark on a journey of precision, innovation, and unmatched quality with us.

FAQs

This plating is an electroplating process that involves depositing a thin layer of tin onto the surface of a metal component. It provides various benefits, including corrosion resistance, solderability, improved conductivity, and enhanced aesthetics.

This plating improves solderability, facilitating the bonding of components during assembly. Tin plated parts usually have a smooth and visually appealing finish, making it ideal for decorative applications as well.

Tin plating is widely used in industries such as automotive, electrical, electronics, telecommunications, aerospace, and more. It is commonly applied to components such as connectors, terminals, fasteners, pressings, and various electro-mechanical parts.

A professional plating company brings expertise, experience, and specialised equipment to ensure optimal results. They have the knowledge to recommend the appropriate tin plating thickness, finish, and pre-plate treatments based on your specific requirements. Professional companies adhere to industry standards, employ rigorous quality control processes, and offer reliable and consistent tin plating services.

Yes, at EC Williams, we have the capabilities to handle both small and large volume tin plating projects. Our state-of-the-art facilities and advanced processing techniques enable us to accommodate a wide range of batch sizes and meet the diverse needs of our customers.

Yes, in addition to tin plating, we offer a range of complementary services. These may include post-tin finishing treatments such as anti-tarnish dips, lubricants, and other protective coatings. We also provide expert technical support and advice to help you achieve the desired results for your components.

Getting started with our plating services is easy. Simply fill out the contact form on our website or reach out to us directly with your requirements. Our dedicated team will respond to your inquiry within 48 hours, providing you with the necessary information and guidance to proceed with your tin plating project.

Each offers unique aesthetic and functional benefits tailored to diverse industry needs.

From reducing friction to enhancing corrosion resistance, our finishes ensure components last longer and perform better.

Post Plating Treatments and Quality Control

Our offerings extend to comprehensive post zinc nickel plating treatments including chromate passivates in trivalent clear and black nickel plating finishes, top coats such as silicate sealants, torque control lubricants, and de-embrittlement facilities for high tensile fasteners and springs.

We maintain top-notch quality standards with X-Ray Fluorescence test equipment certifying the coating thickness and the alloy content of the zinc nickel deposited.