Black Trivalent Zinc Plating Specialists

Call 0121 236 2524 For Your Free No-Obligation Quote

Advanced, environmentally compliant corrosion protection – now fully automated at EC Williams.

What is Black Trivalent Zinc Plating?

Black trivalent zinc plating is a surface finishing process that involves applying a layer of zinc followed by a trivalent chromium-based black passivate. This method offers superior corrosion resistance, a uniform black aesthetic, and full RoHS and REACH compliance. Unlike hexavalent chromates, trivalent finishes are non-toxic and environmentally friendly, making them ideal for modern manufacturing standards.

Common Applications:

- Automotive: underbody fasteners, brake fittings, trim components.

- Defence: structural brackets, ruggedised casings.

- Electrical: terminals, switchgear, enclosures.

- General engineering: high-performance fasteners and components.

Advantages of Black Trivalent Zinc and Zinc Nickel Finishing

- Up to 750 hours corrosion resistance (white rust).

- Uniform, satin black finish.

- Fully compliant with RoHS & REACH.

- Ideal for bonding and adhesive applications.

- Compatible with sealants and topcoats.

- Free from hexavalent chromium.

- Lower environmental impact.

Fully Automated Zinc & Black Trivalent Line

In 2025, EC Williams launched its fully automated line for zinc and black trivalent plating – a major investment that ensures:

- High-capacity throughput.

- Increased process consistency.

- Tighter quality control.

- Scalable production for OEMs.

- Shorter lead times for urgent and repeat orders.

This innovation allows us to meet high-volume and high-precision requirements from sectors like automotive and aerospace without compromising on quality.

Black Trivalent vs Black Oxide vs Hexavalent Chromate

| Feature | Black Trivalent | Black Oxide | Hexavalent Chromate |

|---|---|---|---|

| Corrosion Resistance | Moderate | ||

| Appearance | Satin Black | Dull Black | Glossy Black |

| RoHS Compliant | |||

| Environmental Risk |

Why Choose EC Williams?

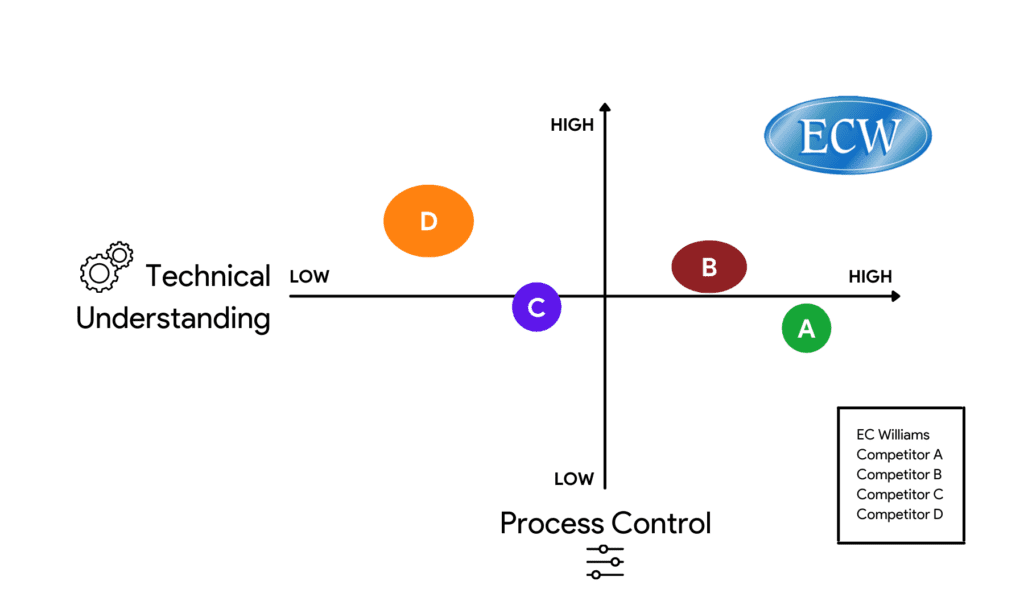

With over 75 years of experience in electroplating and surface finishing, EC Williams is a trusted name in the UK for high-quality metal finishing.

Our Birmingham-based factory serves clients across the UK and Europe, offering:

- Minimum order value from £125.

- Industry-leading turnaround times.

- Reliable process control and quality assurance.

- Technical expertise in corrosion-resistant finishes.

Technical Specifications

| Base Finish | Zinc or Zinc Nickel |

| Passivation | Trivalent Black Chromate |

| Corrosion Resistance | 500-750 hours to white rust |

| Standards | ISO 4520, RoHS & REACH compliant |

| Appearance | Satin black |

FAQs

Automotive, defence, electrical and general engineering sectors commonly use it for both functional and decorative applications.

Black trivalent offers significantly better corrosion resistance and environmental safety than black oxide, with a longer-lasting finish.

Yes. With proper topcoats, black trivalent finishes can be used in harsh environments with extended corrosion protection.

Absolutely. Our automated line is built for scale and can efficiently process high-volume, high-spec orders.

Typical turnaround is 5-7 working days, but expedited options are available for urgent requirements.

Ready to Place an Order?

If you need high-quality black trivalent zinc plating with consistent results, rapid lead times, and scalable capacity, speak to our team today.

Call: 0121 236 2524 | Email: plating@ecwilliams.co.uk

Minimum order value: £125

Post Plating Treatments and Quality Control

Our offerings extend to comprehensive post zinc nickel plating treatments including chromate passivates in trivalent clear and black nickel plating finishes, top coats such as silicate sealants, torque control lubricants, and de-embrittlement facilities for high tensile fasteners and springs.

We maintain top-notch quality standards with X-Ray Fluorescence test equipment certifying the coating thickness and the alloy content of the zinc nickel deposited.