Zinc Nickel Plating

Zinc Nickel Plating – Call 0121 236 2524 – Electroplating Experts

Unmatched Zinc Nickel Plating Services in Birmingham

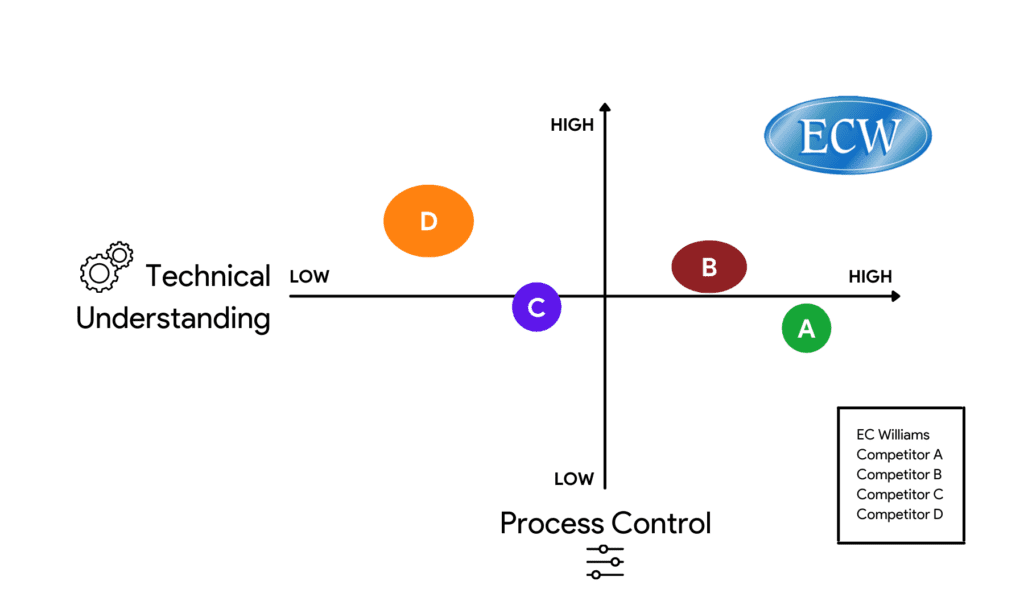

Welcome to EC Williams, one of the UK’s top-rated zinc nickel plating companies offering cutting-edge electroplating solutions. With our plating services grounded in exceptional quality and capacity, we’re the preferred choice for manufacturers. In industries such as the automotive, electronics, fasteners, and pressing sectors.

What is Zinc Nickel Plating?

Zinc nickel plating is a sacrificial anodic coating offering enhanced corrosion protection for components across various industries. Furthermore, the demand for this type of service has surged due to its remarkable performance in industries. These including the automotive and industrial sectors. For automotive applications we offer PPAP Level 3 support as well as IMDS information.

The Zinc Nickel Plating Process

Our zinc nickel plating process starts with designing electrochemical alloys to meet the increased corrosion performance demand from anodic coatings. The alkaline and acid chemistry types in zinc nickel alloy systems are chosen carefully to provide high-performance solutions. Our expertise in this process sets us apart from other companies.

Why Choose This Type Of Plating?

Over the past decades, this type of plating’s popularity has risen owing to its excellent corrosion protection when applied over ferrous substrates. While it offers a protective sacrificial layer to cast iron and steel, its environmental safety compared to toxic alternatives like cadmium makes it a more preferable choice.

Gamma Phase Zinc-Nickel

We utilise the gamma phase zinc-nickel (γ Zn-Ni) in our plating process, known for its superior corrosion resistance and ductility when applied over cast iron or steel. Moreover, the preferred specification for our electroplating industry falls between 12 – 16 wt% nickel, though we can accommodate ranges from 10 – 18 wt%.

Leading Zinc Nickel Plating Suppliers in the UK

As leading zinc nickel platers, we provide services tailored to the needs of our diverse clientele. We strive to meet the demands of the industry in terms of quality, speedy turnaround, and handling both large and small batch sizes.

Our Advanced Barrel Lines

We house one of the most advanced barrel lines, controlled by a software-driven system ensuring consistency and quality control. This state-of-the-art line meets the stringent demands of our industrial customers and OEM customers.

Our Competitive Zinc Nickel Plating Cost

We ensure our the cost of zinc nickel coating and plating is consistently competitive thanks to our flexible capacity and accurate pricing system. Our in-house laboratory, helmed by trained electroplating technicians, enables us to maintain excellent consistency in our finishes.

Post Plating Treatments and Quality Control

Our offerings extend to comprehensive post zinc nickel plating treatments including chromate passivates in trivalent clear and black nickel plating finishes, top coats such as silicate sealants, torque control lubricants, and de-embrittlement facilities for high tensile fasteners and springs.

We maintain top-notch quality standards with X-Ray Fluorescence test equipment certifying the coating thickness and the alloy content of the zinc nickel deposited.

Contact Us Today

For more information about our zinc nickel plating process and costs, visit our website today.

Alternatively, call 0121 236 2524 to speak to a member of our friendly team who can help find the right process for your application.

Trust EC Williams, premium zinc nickel platers in Birmingham, to provide you with unrivalled electroplating services.

FAQs

This plating offers several benefits over traditional zinc plating. The primary advantage is its superior corrosion resistance, which is particularly useful in harsh environments like those encountered in the automotive and marine industries. Zinc nickel coating can provide protection against rust for significantly longer periods. It also offers better thermal stability, which means it maintains its integrity in high-temperature applications. Additionally, it is more wear-resistant and has greater ductility, making it ideal for parts that undergo a lot of stress or movement.

This type of plating is considered more environmentally friendly than some other metal finishing options, such as cadmium plating, which is toxic. EC Williams uses a process that minimises hazardous waste and adheres to strict environmental regulations. Our plating solutions are designed to be safer for both the environment and our workers, with a commitment to sustainability and reducing our ecological footprint.

Yes, this type of plating is an excellent choice for components exposed to high temperatures. It maintains its physical and protective properties at higher temperatures better than many other platings. This makes it an ideal coating for parts used in automotive engines, industrial machinery, and other high-temperature applications.

EC Williams offers a range of post-plating treatments to enhance the performance and aesthetics of components. These include chromate passivates in trivalent clear and black zinc nickel plating to increase corrosion resistance, silicate sealants for added protection, and torque control lubricants to ensure consistent assembly standards. We also provide de-embrittlement services for high tensile fasteners and springs, ensuring they retain their strength and resilience after plating.

At EC Williams, we ensure the quality of our zinc nickel plating through rigorous quality control measures. Our advanced barrel lines are managed by a software-driven system for consistent application. We perform X-Ray Fluorescence testing to certify the thickness and alloy content of our zinc nickel coatings, ensuring they meet the exact specifications required by our clients.